Explanation of Precautions in Handling Geared Motors

In recent years, there has been a growing demand for miniaturization and weight reduction of various devices and equipment, and geared motors, that can provide both high torque and compactness, have been attracting attention. Geared motors have many advantages, but they also require more care in handling than regular motors, so it is important to use them with the appropriate knowledge.

This article therefore explains the precautions that should be taken when handling geared motors.

contents[非表示]

What is a Geared Motor?

A geared motor is a type of motor that combines a motor and a gear box (gear reducers).

In the past, when wanting to reduce the speed of the motor, the main method was to connect the motor and gears using a component called a coupling (joints), but this required more space for the coupling. The geared motor saves space by directly connecting a dedicated gear to the motor.

The following article provides detailed information on examples and types of geared motors.

What is a Geared Motor? Detailed Explanation of Examples of Use and Types of Reduction Gears

Role of Gears (Gear Reducers)

Gears (gear reducers) have four main roles:

- Increasing the output

- Accommodating high rotational speeds

- Accommodating low rotational speeds

- Ensuring the same input and output gear rotation

The torque and speed of a motor are inversely proportional to each other, so the higher the torque, the lower the speed. The reduction ratio, which is the rate at which the gear reduces the motor's rotational speed, is calculated by the formula input speed divided by output speed. In other words, the higher the reduction ratio, the lower the rotation speed and the higher the torque. As the required torque and speed vary depending on the application, an appropriate reduction ratio must be selected.

For example, industrial robots that lift heavy objects often use gears with a large reduction ratio because torque is more important than high-speed drive.

Precautions in Handling Geared Motors

In order to fully utilize the performance of geared motors, it is important to handle them with the appropriate knowledge. Incorrect usage can lead to malfunctions and problems, therefore we will explain the five main precautions in handling.

▼Precautions for Handling the Output Shaft

Avoid rotating the geared motor from the output shaft side. It may cause the internal gears to break.

▼Cautions for Additional Modification

Do not disassemble, modify, or perform any additional process. Not only will the guaranteed performance not be achieved, but it may also cause an unexpected accidents.

▼Precautions Concerning Wiring

When wiring geared motors, always perform grounding work and install a dedicated earth leakage circuit breaker for each unit. Electrical wiring and wiring work must be carried out in accordance with technical standards for electrical equipment and the internal wiring regulations of each power company.

▼Precautions for Usage

Do not use geared motors for indoor use outside. Rainwater, etc. may enter the inside of the motor, resulting in gear malfunction or electrical leakage. Do not continue to drive the motor at an output exceeding the rated output, even if it is within the motor's maximum output range. This may cause the motor to emit smoke or catch on fire, and excessive load on the gears may cause them to break.

▼Precautions Concerning Application

The Building Standards Act prohibits the use of geared motors for lifting people. If a geared motor is used for lifting objects other than people, a safety device must be installed on the machine side.

Mabuchi Motor’s Lineup of Geared Motors

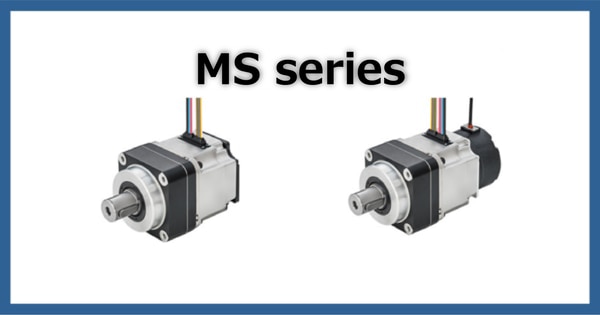

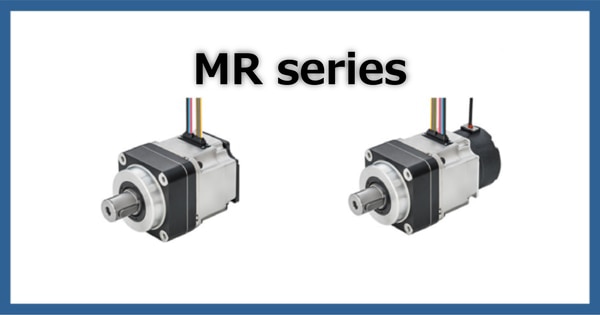

Mabuchi Motor offers several compact and lightweight geared motors. In this article, we will introduce the ‘MS Series’ and ‘MR Series.’ Both are motor series designed for AGV/AMR and personal mobility devices, contributing to miniaturization and weight reduction of applications. Both series feature a water resistant design and can be used outdoors.

As well as individual motors, drive units combined with static brakes and other accessories are also available, allowing for optimal motor selection to suit the product. MR series is also equipped with a high-resolution resolver, making it ideal for applications requiring precision control, such as smooth turning and accurate stopping.

Details of MS Series and MR Series geared motors offered by Mabuchi Motor, as introduced here, can be found below.

If you are considering the introduction of geared motors, please refer to the following pages.

Summary

This article provided the following information on the handling of geared motors.

- What is a Geared Motor?

- The Role of Gears (Gear Reducers)

- Precautions in Handling Geared Motors

Mabuchi Motor’s Lineup of Geared Motors Geared motors, in which the motor and gear box are combined eliminate the additional couplings (joints) which were used to connect the motor and gears, and save space. In order to achieve the maximum performance of geared motors, it is important to fully understand their features and take precautions regarding handling, such as wiring and usage.

Mabuchi Motor manufactures and sells a wide variety of motors, including geared motors such as the ‘MS series’ and ‘MR series.’ If you are interested in our products, please feel free to contact us.

Contact Us

Documents Download