What is a Geared Motor? Detailed Explanation of Examples of Use and Types of Reduction Gears

Geared motors, in which the motor and reduction gear are integrated into a single unit, are utilized at various sites because they can achieve lower revolutions and higher torque than motors alone. The introduction of geared motors contributes to the downsizing of motors and reduction of rotation speed.

Since there are many types of gear reducers for geared motor, it is important to select the appropriate one for the application.

This article will therefore provide an overview of geared motors and the types of reduction gears in detail.

contents[非表示]

- 1.What is a Geared Motor?

- 2.Geared Motors Application Examples

- 3.Type of Reduction Gears for Geared Motors

- 3.1.(1) Parallel Shaft Reduction Gears

- 3.2.(2) Planetary Gear Reducers

- 3.3.(3) Gear Reducers with Orthogonal Axes (Worm and Hypoid)

- 3.4.(4) Cycloid Reduction Gears

- 3.5.(5) Strain Wave Gear Reducers

- 4.Points to Note when Introducing Geared Motors

- 4.1.(1) Space must be Reserved for a Reduction Gear

- 4.2.(2) Use Dedicated Motors for Equipment Used Outdoors.

- 5.Summary

What is a Geared Motor?

A geared motor is a product that combines a motor and reduction gear into a single unit.

In the past, when it was necessary to reduce the speed of a motor, a coupling (joint) was generally used to connect it to a reducer. This method required a space for the motor, reducer, and coupling together.

The geared motor was created to solve this space problem. By coupling a dedicated reduction gear to a direct coupled motor, space can be reduced.

In addition to using a reduction gear, an inverter can also be used to lower the rotation speed, but this method does not increase torque, unlike when a reduction gear is connected. On the other hand, a geared motor is integrated with a reduction gear, so it can achieve both low rotation speed and high torque while saving space.

Geared Motors Application Examples

Geared motors are used in a wide range of large and small machines.

▼Examples of geared motor use

- Food Processing Machines

- Multistory Packing Space

- General-Purpose Conveyors

- Mixer

- Semiconductor Manufacturing Equipment

- Woodworking Tools

- AGV (Automated Guided Vehicle)/AMR (Autonomous Mobile Robot)

- Personal Mobility Vehicles

- Power Windows

- Agricultural Machinery (Mini Tillers)

Products commonly seen in everyday life, such as electric shutters, car washes, power windows play an active.

Mabuchi Motor's geared motors have been used in AGVs (automated guided vehicles), AMRs (autonomous mobile robots), personal mobility vehicles, agricultural machinery (mini tillers), and many other applications.

Type of Reduction Gears for Geared Motors

There are various types of gear reducer parts in geared motors, each suitable for different applications. Understanding the differences between reduction gears will help you select the most effective motor for your purpose.

The following is a list of typical gear reducers used in geared motors.

(1) Parallel Shaft Reduction Gears

Parallel shaft reduction gears are the most common type of reduction gears that use a combination of spur gears. They have excellent connectivity with equipment and are suitable for installation on a flat surface.

Another feature is the large backlash, which is the intentional gap between gears when they mesh. Large backlash makes it difficult to achieve high-precision operation as well as vibration and noise.

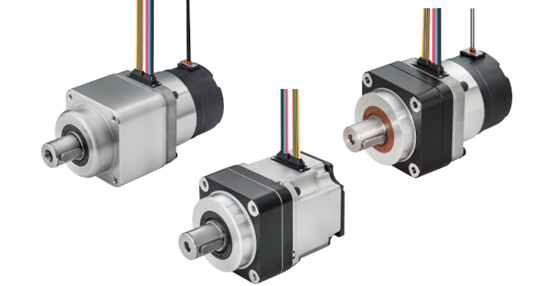

(2) Planetary Gear Reducers

Planetary gear reducers have an internal structure similar to the solar system and the planets orbiting it.

Four components are used inside a planetary gear reducer: sun gear, planetary gear, internal gear, and planetary gear carrier. When the sun gear, which is the input shaft, is rotated by the motor power, the planetary gear rotates and the reduced power is transmitted from the output shaft fixed to the planetary gear carrier.

(3) Gear Reducers with Orthogonal Axes (Worm and Hypoid)

Gear reducers with orthogonal Axes include worm reduction gears and hypoid reduction gears.

A worm reduction gear is a reduction gear that uses a worm gear that rotates in combination with a threaded worm and a helical gear. Hypoid reduction gears, on the other hand, use gears in which the input and output shafts are in a twisted position.

(4) Cycloid Reduction Gears

A cycloid reduction gear is a reduction gear that uses gears with trochoidal curves. They offer high efficiency and excellent shock resistance, and are used in automobile engines, robots, and other applications where high torque is required.

Compared to angular gears, these gears have less friction, enabling high-precision operation and a longer service life.

(5) Strain Wave Gear Reducers

The strain wave gear reducers, developed by American inventor Masser, utilize the elastic mechanics of metal to enable fast and precise movement. Strain Wave reduction gears generally consist of three parts: a wave generator, a flexspline, and a circular spline.

Wave gear reducers have no backlash and are therefore highly accurate for positioning, and are used in robot joints and other applications that require controllability.

Points to Note when Introducing Geared Motors

When introducing geared motors for the first time, there are some points to keep in mind. Checking the often-overlooked points to be aware of will ensure a smooth introduction.

(1) Space must be Reserved for a Reduction Gear

Because geared motors incorporate a reduction gear, they require more space than ordinary motors, although they are more space-saving than those directly coupled with couplings.

As described in the section "Types of gear reducers for geared motors” there are several types of geared motors, including parallel and orthogonal axes, each of which requires a different space.

The orthogonal axes type is useful in situations where space is limited because the direction of the output shaft of the motor section and the shaft of the reducer section are orthogonal and the motor can be placed at right angles to the load shaft.

(2) Use Dedicated Motors for Equipment Used Outdoors.

If geared motors are used in outdoor equipment, dedicated motors must be selected.

If a motor with indoor specifications is used, dust, rainwater, and other contaminants can enter the motor, resulting in electrical leakage and poor lubrication. It is essential to take measures such as introducing motors with dustproof and waterproof specifications or fitting covers on the motors to match the environment in which they will be used.

Summary

In this article, we have explained about geared motors as follows.

- What is a geared motor?

- Geared motor application examples

- Type of reduction gears for geared motors

- Points to note when introducing geared motors

Geared motors are useful when you want to achieve both low RPM and high torque while saving space. Since there are many different types of gear reducer parts, it is important to understand the characteristics of each and select the product that best suits your purpose.

For AGVs (automated guided vehicles), AMRs (autonomous mobile robots), and personal mobility vehicles, we recommend Mabuchi Motor's MS series and MR series. Our representatives will support you when purchasing motors, so even first-time customers can use our motors confortably.

If you are interested in our products, please feel free to contact us.

Contact Us