Comparison of features and differences between DC motors and AC motors

Motors are divided into two types: Direct Current (DC) motors and Alternating Current (AC). They are utilized in various fields such as automobiles, medical equipment, and industrial robots.

When considering the purchase of a motor, some people may be wondering which one to choose.

This article explains the features of DC and AC motors and the differences between them.

This article also explains how to select an Industrial Motors.

【How to Select an Industrial Motor】Introduction of Motor Types and Selection Points

contents[非表示]

- 1.Features of Direct Current (DC) Motors

- 2.Features of Alternating Current (AC) Motors

- 3.Difference between DC and AC Motors

- 3.1.①Rotation Control

- 3.2.②Noises

- 4.Mabuchi Motor’s Sustainable Manufacturing

- 4.1.①Realization of Resource and Energy Conservation

- 4.2.②Production Processes that Do Not Use Environmentally Hazardous Substances

- 5.Summary

Features of Direct Current (DC) Motors

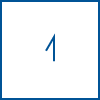

DC Motors are motors which are powered by positive and negative currents that always flow in a constant direction.

Typical examples of current used in DC motors are dry cell batteries and batteries. When using them, the positive and negative directions are specified because the current flows in a constant direction.

▼Image of DC Motor

DC motors are characterized by their low cost, compact size, high output, and superior energy conversion efficiency. Another feature is the high starting torque (* 1), which starts up at high speed as soon as the power is turned on.

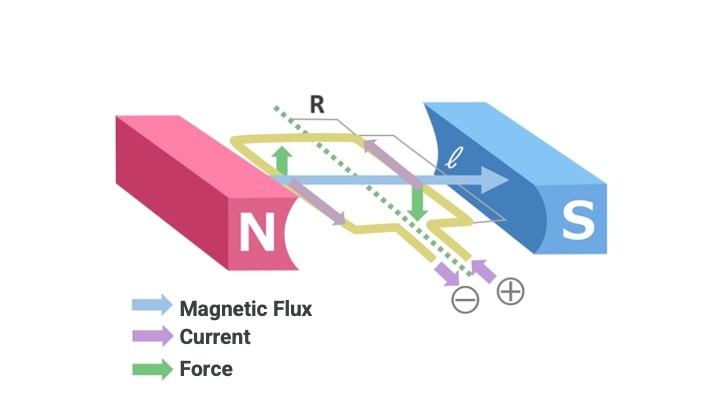

DC motors are divided into brush DC motors and brushless DC motors, with the major difference being the presence or absence of commutator (* 2) and brushes (*3).

*1: Torque generated at the moment a motor starts up from a standstill.

*2: A component that changes the direction of the current flowing in the coil. Also called commutator.

*3: It refers to the electrodes used to conduct the current inside the motor.

The differences between brush DC motors and brushless DC motors are explained in detail in this article. Please refer to it as well.

What is a Brushless DC Motor? Explanation of the differences and types from brush DC motors

Features of Alternating Current (AC) Motors

Unlike DC motors, AC motors are powered by an electric current whose positive and negative directions are periodically switched.

Since there are no brushes inside the motor, AC motors do not require maintenance or motor replacement and can be used for a long-term period.

AC motors are also powered by electricity transmitted from a power plant. It is important to note that AC motors cannot be used in locations that are not equipped with electrical outlets.

Difference between DC and AC Motors

Differences between DC motors and AC motors can be seen in addition to the difference in power source. Here we explain the differences between the two from three perspectives.

▼Difference between DC and AC Motors

Items |

DC Motors |

AC Motors |

①Rotation Control |

Easy to control |

Hard to control |

②Noises |

likely to occur |

Less likely to occur |

③Energy Conversion Efficiency |

Approx. 90% |

Approx. 85% |

①Rotation Control

The first difference is flexibility in motor rotation control.

With DC motors, the rotation speed can be easily controlled by changing the voltage applied to the motor to achieve high speed rotation.

AC motors, on the other hand, have a constant rotation speed depending on the frequency. Since the frequency in Japan is fixed between eastern (50Hz) and western (60Hz) Japan, it cannot be easily switched, making it difficult to control the rotation speed.

Rotation speed can be controlled by using an inverter device that allows the voltage and frequency to be set freely, but the cost of the inverter device is higher than that DC motors.

②Noises

The second difference is the occurrence of noises.

DC motors are equipped with brushes and commutators for the purpose of conducting and redirecting current inside the motor. Noises can occur in DC motors due to friction between the brushes and commutator.

On the other hand, AC motors do not have brushes and commutators, so they are less likely to generate noises.

However, a "brushless DC motor," one of the DC motors, uses a drive circuit with semiconductor elements instead of brushes and commutators. This provides an environment that is less prone to noise generation, like that of AC motors.

Abnormal Noises, a typical motor problem, is explained in this article.

Examples of Motor Problems, Causes of Abnormal Noises, and Countermeasures

③Energy Conversion Efficiency

The third difference is energy conversion efficiency.

In general, motors are said to have higher energy conversion efficiency than internal combustion engines such as gasoline and diesel engines. This is due to their ability to generate power even at low RPMs and to generate less heat.

▼Differences of Energy Conversion Efficiency

Classification |

Approximate Energy Conversion Efficiency |

Internal Combustion Engines |

Approx. 30-40% |

DC Motors |

Approx. 90% |

AC Motors |

Approx. 85% |

A comparison of motors by type, known as high energy conversion efficiency, shows that DC motors are about 5% higher than AC motors. Since DC motors are superior in miniaturization, they are expected to reduce the amount of energy required, resources needed to manufacture components.

Source: Ministry of Economy, Trade and Industry, "Criteria for Judgment, etc. by Manufacturers of Energy Consuming Equipment, etc. concerning Improvement of Energy Consumption Performance of AC Motors."

Mabuchi Motor’s Sustainable Manufacturing

Mabuchi Motor, which handles DC motors, aims for "clean manufacturing" throughout the entire supply chain.

In addition, we have set forth "We will pursue the full range of possibilities of small DC motors to help resolve issues confronting global society through motors." in our Sustainability Policy. We are working on development every day with this in mind.

Here we introduce two features of Mabuchi Motor's sustainable manufacturing.

①Realization of Resource and Energy Conservation

At Mabuchi Motor, we have focused our research and development efforts on motors that are compact, lightweight, highly efficient, and quiet. As a result, we have been able to provide products that contribute to improved fuel efficiency, resource conservation, and energy conservation in various types of equipment.

Some of our motors have recorded an energy conversion efficiency of 92%, contributing not only to energy conservation but also to improved environmental performance.

②Production Processes that Do Not Use Environmentally Hazardous Substances

Mabuchi Motor products do not contain environmentally hazardous substances such as hexavalent chromium, cadmium, and lead. This prevents the occurrence of environmental accidents.

We are also reviewing our production processes in consideration of the environment, and have actually implemented the following initiatives.

▼Examples of Production Process Improvements

- Changed cleaning solution for motor parts from alkaline detergent to alkaline electrolyzed water

- Installed a filtration system to circulate and reuse cleaning solution

- Improved production equipment and inspection processes to make some motor components wash-free.

Summary

In this article, the following information on DC and AC motors was explained.

Features and Differences between DC and AC Motors

Mabuchi Motor's Commitment to Sustainable Manufacturing

The main difference between DC and AC motors is the power source that conducts electricity to the motor. There are also differences in ease of rotation control, noise generation, and energy conversion efficiency. DC motors are known to be easier to handle and more energy efficient.

Mabuchi Motor handles DC motors, and in recent years, we have been particularly focusing on the development of brushless DC motors. Mabuchi Motor offers a lineup of products based on "compact, lightweight and highly efficient" motors, incorporating the elements required for each application, such as “waterproofing, high-speed rotation, and quiet operation”.

We have a worldwide sales network that enable us to deliver your desired product in a short period of time. We also provide consistent support from product selection to post-purchase, including requests for samples and confirmation of usage. Please feel free to contact us if you have any questions or concerns, such as "I don't know which motor is best for my product" or "I am looking for a motor with high energy efficiency."