Examples of motor problems, causes of abnormal noise, and improvement solutions

Motors are used in a wide variety of products, including electrical appliances, autonomous transport robots, personal mobility devices, motors for driving automobiles, and air conditioner compressors.

In the field where motors are handled on a daily basis, some people may have problems such as "unstable motor operation," "occasional abnormal noise," and "failure to produce values according to specifications”. To prevent motor failures and create a safe manufacturing environment, it is necessary to know the motor problems that are likely to occur and respond appropriately.

This article focuses on "abnormal noise" based on examples of typical motor problems, explaining the causes and solutions. It also introduces the features of Mabuchi motors for those who are considering purchasing a new motor.

contents[非表示]

Examples of Typical Motor Troubles

Motor troubles can be divided into three main categories: heat generation, vibration, and abnormal noise. Possible causes for each type of trouble are listed below.

Type |

Examples of Possible Causes |

Heat generation |

|

Vibration |

|

Abnormal Noise |

|

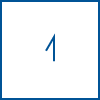

▼Motor parts

Motor operation can be affected by various causes, such as the motor installation environment and damage or deterioration of parts.

*A bearing is a component that supports rotating parts in the correct position to facilitate rotation.

[By Source] Causes of Noise and Countermeasures

The type and cause of motor noise are not uniform, as the sound heard varies depending on the machine in which it is installed. In some cases, the noise is caused by compatibility between the motor and the machine in which it is installed, depending on the weight and structure of the machine.

Here, the types of abnormal noise are explained by dividing them into two major categories based on the source of the sound rather than the sound heard.

Electrical Noise

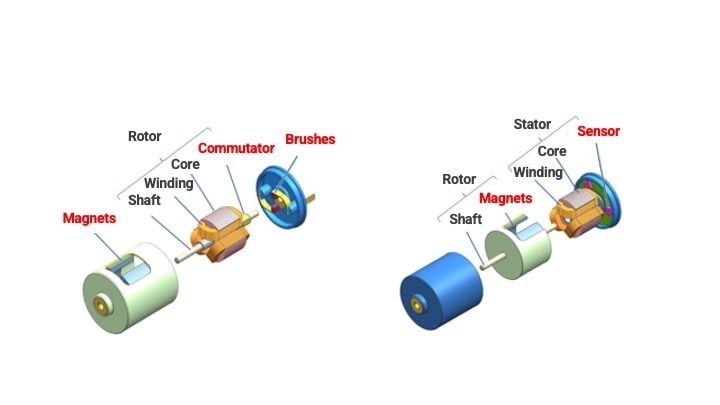

When electrical noise is generated in a DC motor, the spark generated by the friction between the brush (1) and commutator (2) used for commutation of electricity may be heard as noise in some cases.

▼ Image of electrical noise generation

There are three reasons for sparking

- The carbon brushes and special alloy metal plates that are installed to ensure smooth contact between the brushes and commutator are worn out.

- The motor is under a greater load than it is rated for, or a large current is flowing through it.

- Shaft lubricant has flowed into the contact area of the brushes and commutator, forming a film that does not conduct electricity.

*1・・・A component that changes the direction of the current flowing in the coil. Also called commutator.

*2・・・・Electrodes for passing current inside the motor.

Countermeasures

The most common countermeasure to reduce electrical noise is to install a capacitor or choke coil in the rotor section. Specifically, the following two measures are available.

Effective frequency band |

Measures |

High frequency band |

Install four components that are noise eliminating elements inside the motor

|

Low frequency band |

Install two components that serve as noise eliminating elements outside the motor

|

Each of these measures can be implemented not only independently but also in combination for higher effectiveness.

Mechanical Noise

Mechanical noise, such as the sound of friction between parts and the violent vibrations of the motors, is another cause.

The following six are examples of mechanical noise.

▼Examples of causes of mechanical noise

Type of sound |

Details |

Brush sliding sound (*) |

Sound of friction between brush and commutator |

Shaft sliding sound |

Friction sound between shaft and bearing |

Clearance sound (rumbling sound) |

Among shaft sliding sounds, a harsh sound with a cause |

Resonance sound |

Shaking sound of the case that occurs only at a specific rotation speed or frequency range |

Thrust sound (knack sound) |

Tapping sound caused by axial movement and vibration of the rotor |

Wind noise |

Wind noise that occurs when there is a cooling fan inside the motor |

*Sliding sound is a sound generated by friction between objects.

Countermeasures

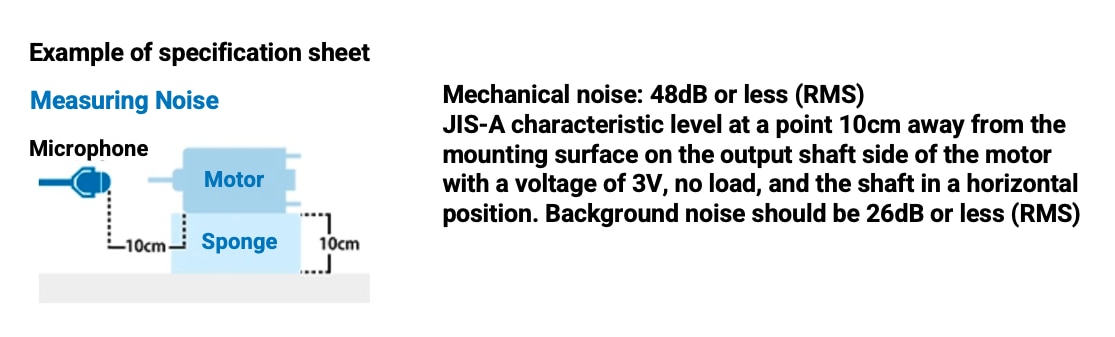

it is important to know the criteria for determining the level of noise to be repaired or replaced as "abnormal noise. For this purpose, we use a sound level meter to measure the loudness of machine noise, and note it in the delivery specifications.

When measuring, it is common to use a frequency correction (auditory correction) called "JIS-A characteristics" .

In addition, before measurement, it is necessary to define the voltage, rotation speed, load, side pressure, motor attitude, microphone position, background noise, etc.

▼Image of the description in the delivery specifications

We have described the causes and countermeasures for electrical and mechanical noise, but there may be cases where "it is difficult to handle problem in-house" or "It is unclear which part of the motor is making the noise. Having a specialized company repair the motor or purchasing a new motor are efficient and effective solutions.

SUMMARY

This article has described the following troubles with motors.

- Typical motor troubles

- Types of Abnormal Noise and Countermeasures

Motor troubles can be divided into three categories: heat generation, vibration, and abnormal noise. Types of abnormal noise include electrical noise and mechanical noise. These are caused by resonance noise due to sparks and vibrations generated by friction between motor parts, and friction noise from parts.

Countermeasures include installing noise-eliminating elements inside and outside the motor and measuring the noise level, but it is recommended to have a specialized company repair the motor or purchase a new motor.

Mabuchi Motor offers a lineup of products that incorporate the elements required for each application, such as waterproofing, high-speed rotation, and quietness, based on our "compactness, light weight, and high efficiency.

In addition, we have a worldwide sales network that enables us to deliver the desired product in a short period of time.

Furthermore, we provide consistent support from product selection to post-purchase, including requests for samples and confirmation of usage. Please feel free to contact us if you have any questions such as "I want to purchase a motor that meets the specifications" or "I am looking for a motor that is less likely to cause trouble.

Inquiry

If you are looking for industrial motors, please refer to this article.

【How to Select an Industrial Motor 】 Introduction of Motor Types and Selection Points

Features and Recommended Models of Mabuchi Motor Products

When purchasing a motor, it is also important to choose a product that is of high quality and less likely to cause problems.

While Mabuchi Motor handles many brushed DC motors, we also focus on the development of brushless DC motors. We not only develop products with superior functionality, but have also established a system that allows us to continue to provide a stable supply of high-quality, reasonably priced products to all parts of the world.

In addition, we are constantly striving to improve customer satisfaction, and our products are used in a wide range of industries, including the automotive and medical industries.

Furthermore, Mabuchi Motor's "High-Speed Brushless Motor Series" has been highly evaluated for its quietness, low vibration, efficiency, and durability at high speeds, and has demonstrated high performance in medical equipment for various applications such as ventilators, dental treatment, and surgical operations. Please feel free to contact us if you are considering using our products for non-medical applications.