What is a Pump? Introduction of Rolling Pumps Available at the Mabuchi Group with Explanations of the Different Types

Pumps are used in various aspects of our daily life and industry, but although they are familiar to us, their applications and types may not be well known because they are built into products. Pumps have a wide range of mechanisms and functions, and a wide variety of pumps are used for different purposes.

This article focuses on the types and applications of pumps and explains them in detail.

contents[非表示]

What is a Pump?

A pump is a machine that produces the energy required to move a ‘fluid’ such as liquid or gas, and its performance is expressed in a common measure of ‘flow rate’. The role of a pump is to apply pressure to a fluid to create a steady flow.

In our daily lives, the most familiar and utilized pumps are water and sewage systems. Additionally, small pumps are used in blood pressure monitors and coffee machines, which makes them an essential part of our healthy and prosperous lives.

Types of Pumps

Pumps vary in structure depending on the application and type of fluid, and can be broadly classified into ‘positive displacement pumps’ and ‘turbo pumps’.

Here we take a deeper look at the different types of pumps.

Positive Displacement Pumps

A positive displacement pump is a pump that discharges fluid by pressurizing the fluid in a certain volume of space by reciprocating or rotating motion. It is characterized by their excellent stable flow rate for accurately discharging a fixed amount of fluid, relatively high lifting height*, self-priming capacity and high discharge pressure.

*A numerical value indicating how high a pump is capable of lifting a fluid. For more information on types of positive displacement pumps, see below.

▼ Types of Positive Displacement Pumps

Reciprocating pump |

Piston pump |

Plunger pump | |

Diaphragm pump | |

Rotary pump |

Gear pump |

Screw pump | |

Vane pump |

Positive displacement pumps are classified as ‘reciprocating pumps’ and ‘rotary pumps’, from which they are further divided according to application.

Reciprocating pumps are suitable for applications where fluid pressure is required, and plunger pumps are commonly used in high-pressure cleaners for vehicles and buildings. Rotary pumps consist of intermeshing gears or screws that guide the liquid between the gears, and are suitable for transporting highly viscous liquids such as grease or adhesives.

Turbo Pumps

Turbo pumps are designed to pump fluid by centrifugal force generated by an internally rotating impeller, and are capable of pumping large volumes of fluid continuously. However, they have a low lifting height and the flow rate is largely dependent on the load, so the constant flow rate tends to be lower than positive displacement pumps.

For more information on types of turbo pumps, see below.

▼Types of Turbo Pumps

Centrifugal pump |

Diffuser pump |

Turbine pump | |

Propeller pump |

Axial pump |

Mixed flow pump | |

Viscous pump |

Cascade pump |

These turbo pumps are suitable for applications where the priority is to pump large volumes of fluid continuously rather than a stable flow rate, e.g. diffuser pumps are used for blowers, water and sewage systems, power plants and boiler feed water.

As there is such a wide range of pump types, it is important to select the right pump for the right application.

Applications of Pumps

Pumps are used for delivering, circulating and pressurizing fluids in the medical and industrial fields, as well as in various aspects of daily life.

▼Main Applications for Pumps

- Medical field (small blood pressure monitors, infusion pumps, etc.)

- Circulation of liquids (solvents, refrigerants, etc. in chemical plants)

- Pumping up water (rainwater, irrigation, etc.)

- Pumping (water supply, sewage drainage, etc.)

- Home use (paraffin pumps, bath pumps, etc.)

- Use of hydraulic energy (pumped storage power generation)

Introduction to Rolling Pumps available at the Mabuchi Group

Various types of pumps have been introduced so far, but this section provides a detailed explanation of the rolling pumps handled by Mabuchi Oken, a member of the Mabuchi Group.

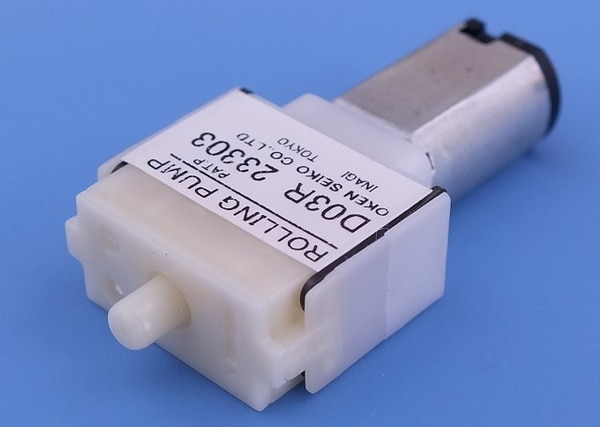

Rolling pumps are small pumps with a rolling drive system among diaphragm pumps, which are a type of positive displacement pump. Rolling pumps were invented by Mabuchi Oken and are widely used in medical equipment such as blood pressure monitors, automotive electrical equipment such as lumbar supports, other household appliances and office equipment.

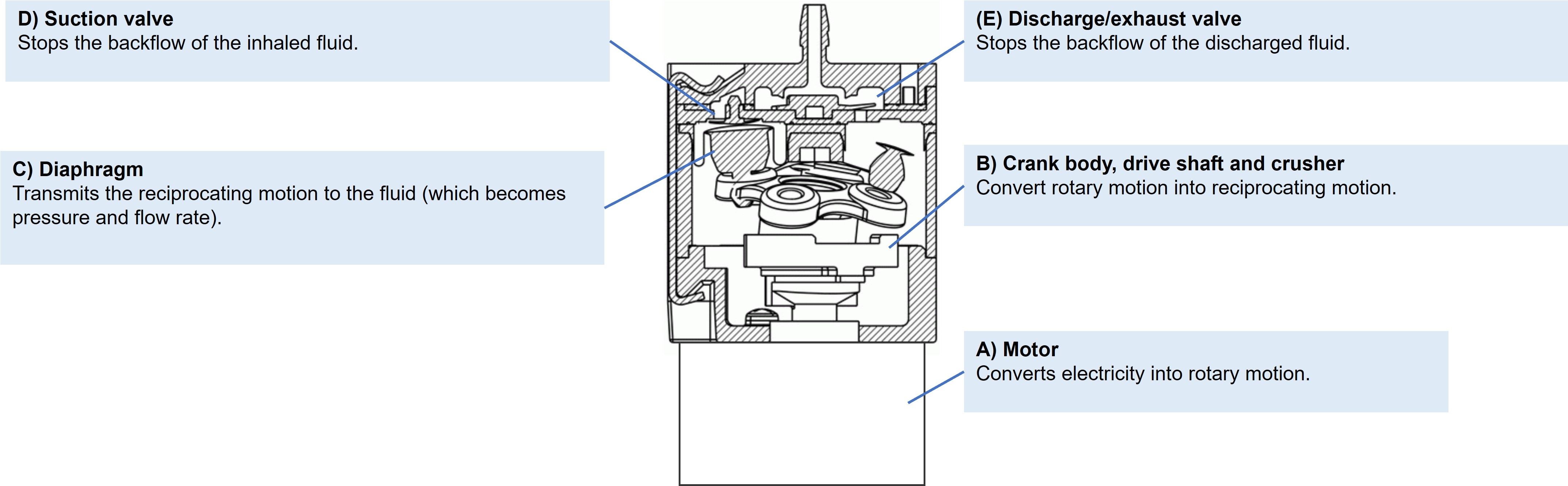

▼ Structural Diagram of a Rolling Pump

Rolling pumps are designed to pump (positive pressure) or suck (negative pressure) fluid by opening and closing intake and exhaust valves through the contraction and expansion of multiple cylinders (diaphragms) by the rotary motion of a motor.

Compared to direct-acting systems, the advantages of this type of pump include low vibration, low operating noise, in addition to reduced pulsation. They can also be designed to be small in size and can be installed on small electronic devices.

The following is a selection of some of the rolling pumps manufactured and sold by Mabuchi Oken.

Please visit the Mabuchi Oken website (https://okenseiko.com/en/pump/air/) for more detailed information.

Air Pumps (Positive Pressure)

These pumps are used for transferring gases (positive pressure). A wide range of product lineups are available, including compact high-flow models and high-pressure models, depending on the required performance.

▼ Ultra-compact air pumps: Size 8 mm thickness

Main applications: Wrist blood pressure monitor

▼ Silent, low-pulsation air pumps: Size φ27 mm

Main applications: Upper arm blood pressure monitor, patient monitor

▼ High-flow air pumps: Size 55mm squared

Main applications: Lumbar support, massage chairs

Vacuum Pumps (Negative Pressure)

These pumps are used for suction (negative pressure) of gases. Mabuchi Oken's vacuum pumps feature high suction pressure despite their compact design.

▼ Vacuum pump: Size φ27 mm

Main applications: Analyzers, vacuum storage containers for food, inkjet printers

Liquid Pumps

These pumps are used for transferring liquids. Mabuchi Oken offers a range of highly versatile liquid pumps that are self-priming and can be placed the pump position regardless of the water level, and have been widely used in various fields such as household appliances and housing equipment.

▼ Liquid pump: Size φ27 mm

Main applications: Microwave ovens (steam function), inkjet printers, dishwashers (detergent supply)

Summary

This article has provided the following information on the types and uses of pumps.

- What is a Pump?

- Types of Pumps

- Applications of Pumps

- Introduction to Rolling Pumps available at the Mabuchi Group

In general, pumps are broadly classified into two types, ‘positive displacement’ and ‘Turbo’, each with a different structure. When selecting a pump, it is important to consider the application and the type of fluid to determine the appropriate type.

Mabuchi Oken, a member of the Mabuchi Group, offers a wide range of small pumps in addition to the products introduced here.

If you are interested in our products, please feel free to contact us.

Contact us at