Slotless vs Slotted Motors: Which Design Is Right?

This article compares slotless and slotted motors from a technical perspective.

By understanding what makes each design unique, you'll be better equipped to choose the right motor for your application.

contents[非表示]

- 1.Comparing Motor Structures

- 2.Feature and Performance Comparison

- 2.1.Features of Slotless Motors

- 2.2.Features of Slotted Motors

- 2.2.1.High Torque Density

- 2.2.2.Thermal Management

- 2.2.3.Lower Manufacturing Cost

- 2.3.Comparison Summary

- 3.Common Applications

- 4.Mabuchi Motor's High-Speed Brushless Motors

- 4.1.Learn More

- 5.Conclusion

Comparing Motor Structures

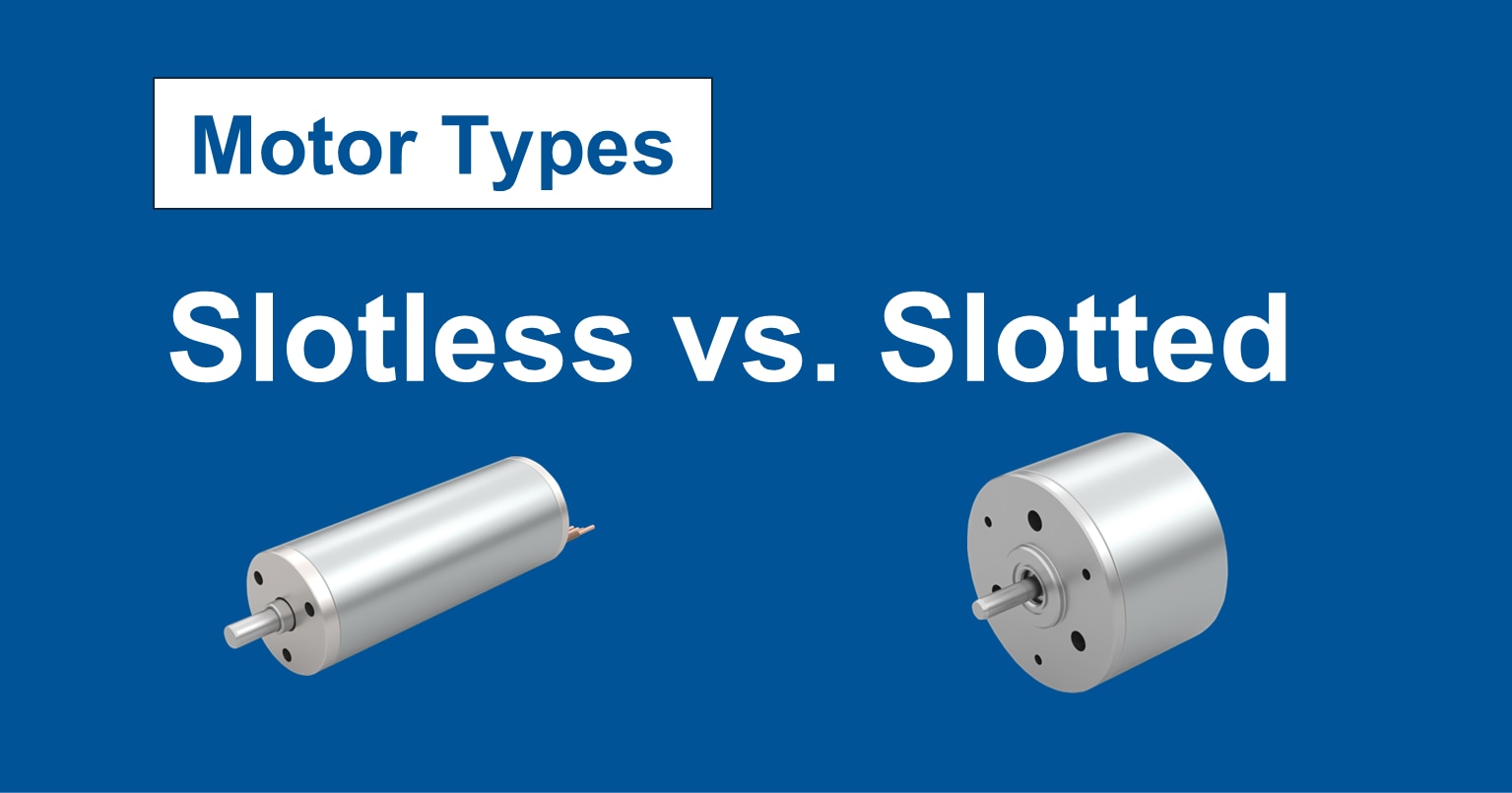

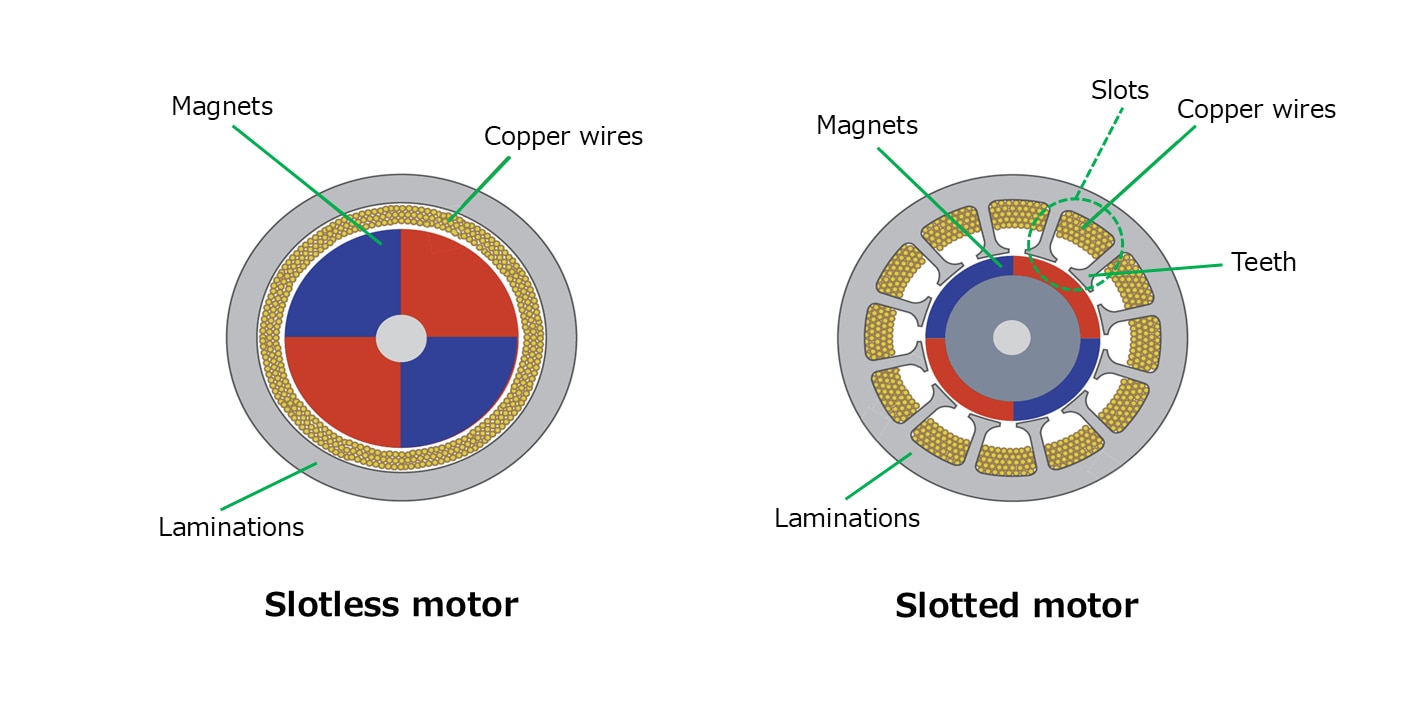

In a traditional DC motor, the stator (or rotor, depending on the design) has slots and teeth that hold the copper wire windings in place. A slotless motor works differently—it has no slots or teeth at all. Instead, the windings are held in position using resin or similar bonding materials.

Figure 1: Structural difference between a slotless motor (left) and a slotted motor (right) (both inner rotor brushless types).

Figure 1: Structural difference between a slotless motor (left) and a slotted motor (right) (both inner rotor brushless types).

The image shows two inner rotor brushless motors side by side. In the slotted motor, you can see how the winding follows the shape of the teeth, wrapping around each one. In the slotless motor, the winding forms a smooth, self-supporting cylinder with no interruptions.

Both motors work on the same basic principle—they generate torque through the interaction between the permanent magnet's magnetic field and the coil's magnetic field.

However, this structural difference in how the windings are arranged creates very different performance characteristics.

Feature and Performance Comparison

The main difference between these two motor types comes down to stator design. This seemingly simple design choice has a significant impact on the motor's electrical and mechanical behavior. Let's look at what each type offers and where they're typically used.

Features of Slotless Motors

Quiet Operation and Low Vibration

In a slotted motor, the teeth create variations in magnetic reluctance (resistance to magnetic flux) as the rotor spins. The permanent magnets are attracted to these teeth, creating a pulsing magnetic force that tries to align the magnets with the teeth. This phenomenon is called cogging torque, and it causes the motor to vibrate and produce noise, even when no current is flowing through the windings.

A slotless motor eliminates this problem completely. Without teeth, the stator presents a smooth, uniform iron surface to the magnets. There's no magnetic variation to create alignment forces, which means virtually no cogging torque. The result is exceptionally smooth, quiet operation—a major advantage in noise-sensitive applications.

High Efficiency

All motors experience iron loss (also called core loss) as the magnetic flux changes direction during rotation. This loss comes from two sources: eddy currents (circular currents induced in the iron) and hysteresis (energy lost as magnetic domains flip back and forth). Both types of loss increase at higher speeds and with greater flux variations.

In a slotted motor, the teeth are a major contributor to iron loss. The magnetic flux concentrates and changes rapidly at the tooth tips, generating significant eddy currents and hysteresis losses. By removing the teeth entirely, a slotless motor dramatically reduces these losses. This translates to higher efficiency across the speed range, with especially noticeable improvements at high speeds. For battery-powered applications, this efficiency advantage also means longer operating times.

Ideal for Miniaturization

The slotted motor's structure creates challenges for miniaturization. The windings must fit into the slots between teeth, which creates an uneven, lumpy profile. This inherently makes the stator thicker than it theoretically needs to be.

A slotless motor avoids this issue. The coil sits on a smooth cylindrical surface, creating a more uniform and compact structure. There are no protruding teeth or deep slots to work around. This streamlined design makes it much easier to reduce the motor's overall size, which is ideal when you're working with tight space constraints or trying to minimize device weight.

Features of Slotted Motors

High Torque Density

When you compare a slotless motor and a slotted motor of the same outer dimensions, the slotted design can typically fit more copper into the same space. The teeth create a framework that supports dense winding patterns, allowing you to pack more wire into each slot.

More copper means the coil can generate a stronger magnetic field when current flows through it. This stronger field interacts more forcefully with the permanent magnets, producing greater torque. In practical terms, a slotted motor delivers more torque per unit volume—what we call higher torque density. If your application needs maximum torque from a given motor size, a slotted design usually wins.

Thermal Management

Heat management is critical for motor reliability and performance. In a slotted motor, the teeth and slots create a direct thermal path from the windings to the stator core, and from there to the motor housing. Heat can flow relatively easily along this path, making it simpler to keep the motor cool during extended operation.

A slotless motor doesn't have this direct thermal path. The windings are typically surrounded by resin or air gaps, which act as thermal insulators. Depending on your duty cycle and how the motor is packaged, you may need to implement additional cooling strategies—such as increased airflow, heat sinks, or lower continuous current limits—to prevent overheating.

Lower Manufacturing Cost

For motors in the same general power range, slotted designs are typically less expensive to produce. The manufacturing process is well-established and relatively straightforward. The teeth provide a natural structure for winding the coil, and the entire assembly can be built using standard, proven techniques.

Slotless motors require more sophisticated manufacturing processes. Without teeth to hold the windings, you need to create a self-supporting coil structure, which involves precise winding techniques and careful resin bonding. The process is more complex and takes longer.

There's another cost factor to consider: to achieve the same torque output as a slotted motor in a given frame size, a slotless motor typically needs stronger (and more expensive) permanent magnets to compensate for its lower copper fill factor. The housing and end bells also require tighter tolerances to maintain the small air gap needed for efficient operation. All of these factors add up to a higher overall manufacturing cost.

Comparison Summary

Feature | Slotless Motor | Slotted Motor |

Cogging Torque | Negligible | Significant |

Efficiency | High (Low Iron Loss) | Lower (Higher Iron Loss) |

Miniaturization | Easier to achieve | More difficult to achieve |

Torque Density | Lower | Higher |

Thermal Management | Often requires additional cooling | More efficient (motor dissipates heat well) |

Manufacturing Cost | Higher | Lower |

Common Applications

Slotless motors excel in applications where smooth, quiet operation is essential. You'll find them in medical devices like dental handpieces and surgical power tools, where vibration could affect precision or patient comfort. They're also popular in small actuators and robot joints that need precise motion control without unwanted oscillations or noise.

Slotted motors are the workhorses of industrial automation. Their combination of high torque output and reasonable cost makes them a natural fit for factory automation (FA) equipment, industrial machinery, and home appliances. When you need reliable, powerful performance without the premium price tag of a slotless design, slotted motors are often the right choice.

Mabuchi Motor's High-Speed Brushless Motors

Mabuchi Motor offers a comprehensive range of both slotless and slotted high-speed brushless motors. We've developed these products primarily for the demanding requirements of medical device applications, where performance and reliability are critical.

Our slotless high-speed brushless motors deliver the low noise and low vibration you'd expect from this design. But we've also developed a proprietary, patented coil design that achieves exceptional torque density—often approaching or matching what you'd expect from a slotted motor. This makes our slotless motors an excellent solution for a wide range of medical applications, including dental handpieces, surgical power tools, and ventilators.

We also manufacture cost-effective slotted models designed for applications like in-home medical equipment, where cost considerations are important but high performance is still required. If you'd like to discuss your specific requirements, please feel free to contact us.

Figure 3: A slotless motor (left) and slotted motor (right) by Mabuchi Motor.

Learn More

Conclusion

Both slotless and slotted motors work on the same fundamental electromagnetic principles, but their different winding structures create important trade-offs that you'll need to consider for your application.

Slotless motors offer clear advantages when you need low noise, low vibration, high efficiency, and compact size. These benefits come at a cost premium and usually with some sacrifice in torque density. Slotted motors take the opposite approach—they accept higher cogging torque in exchange for lower manufacturing costs and the ability to generate more torque in a given frame size.

The right choice depends on what matters most for your specific application. By understanding the core strengths and limitations of each design, you can make an informed decision that balances performance requirements against cost constraints.