What is a Hollow Motor? Explanation of the Main Advantages and Applications

Efficient placement of power supplies and cables is essential for incorporating multiple motors in equipment. In this regard, hollow motors can make effective use of limited space.

Hollow motors have many advantages and are used in a variety of applications. Selecting the right product is important to saving space and reducing equipment size.

This article will provide an overview of hollow motors and explain their main advantages and applications in detail.

contents[非表示]

- 1.What is a Hollow Motor?

- 2.Two Advantages of installing a Hollow Motor

- 2.1.Advantage 1: Reduction of required Parts and Man-Hours

- 2.2.Advantage 2: Miniaturization of Equipment

- 3.Main Applications of Hollow Motors

- 3.1.(1) Compact Robot

- 3.2.(2) Cooperative Robot

- 3.3.(3) Roller Drive

- 3.4.(4) Spin Coater

- 4.Mabuchi Motor's Hollow Frameless Motors

- 5.Summary

What is a Hollow Motor?

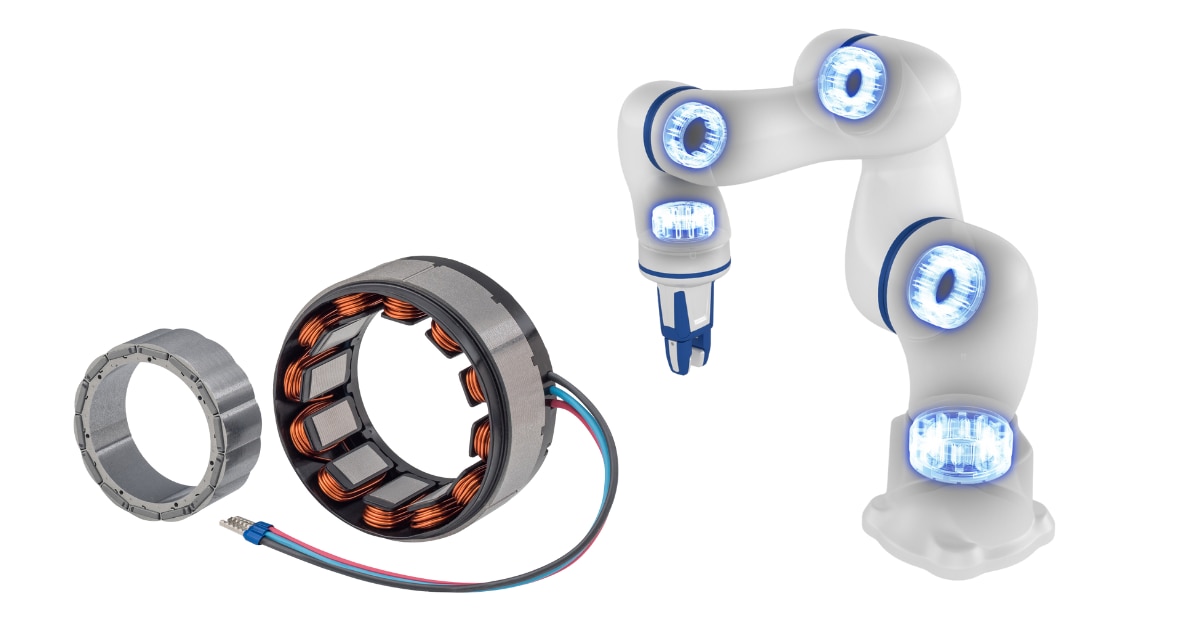

Hollow motors are mainly used in joints of robots and roller drives of conveyor belts. Unlike conventional motors, hollow motors have a hole in the center.

When multiple motors are incorporated in a device, power supply and cables must be efficiently arranged in a limited space. In such cases, the use of hollow motors allows power supply lines, network cables, air tubes, etc. to be placed inside the hollow part, thus saving space.

Two Advantages of installing a Hollow Motor

What are the advantages of using hollow motors in equipment?

In this section, two of the main benefits are explained.

Advantage 1: Reduction of required Parts and Man-Hours

The major advantage of the hollow motor is that it reduces the number of parts required for the equipment and the man-hours involved.

Hollow motors can be combined with linear motion mechanisms such as ball splines inside the hollow shaft. This eliminates the need for timing belts and other large parts that transmit rotation. It also reduces man-hours required for construction and maintenance.

This can lead to significant cost savings, as maintenance work can be reduced, and fewer parts have to be replaced in the event of a breakdown.

Advantage 2: Miniaturization of Equipment

Installing hollow motors saves space, allowing equipment to be miniaturized. Miniaturizing the equipment makes effective use of limited space at the production site, leading to improved operational efficiency and productivity.

Main Applications of Hollow Motors

Hollow motors are used as components in a variety of equipment. Here are some examples of applications utilizing hollow motors.

(1) Compact Robot

Typical products in which hollow motors are used are small robots. As mentioned above, hollow motors are used for arm joints and torso turning of small robots because they reduce the number of parts required for the device compared to conventional motors.

(2) Cooperative Robot

Hollow motors are often used in joints of cooperating robots. The low cogging design enables smooth motion of the robot, and the high-efficiency magnetic circuit design with low energy loss ensures energy-efficient operation even during extended use.

(3) Roller Drive

Hollow motors are also suitable for roller drive units such as belt conveyors. Since the roller shaft can be directly integrated into the hollow point without using a coupling (shaft coupling), a highly efficient design is possible.

(4) Spin Coater

Hollow motors are also used in a coating device called a spin coater. A spin coater is a device that applies a thin, uniform layer of liquid using centrifugal force generated by the rotation of a motor. By using a hollow motor, air can be sucked out of the hollow space to evenly adsorb the coating liquid.

Mabuchi Motor's Hollow Frameless Motors

Mabuchi Motor offers the IA/IB Series of hollow frameless motors. Intended for use in cooperative robots and products with built-in structures, the motors are available in four sizes with different outputs to meet the customer’s specifications.

Hollow frameless motors, as the name implies, have no frame and allow the design engineer to determine the structural plan with the exception of the magnetic circuit. This results in a compact and flexible design. Mabuchi Motor's hollow frameless motors have a low cogging design consisting of a stator and a rotor, which enables smooth motion of the robot.

It also features a highly efficient magnetic circuit design and minimal energy loss. This contributes not only to equipment size and weight reduction, but also to energy conservation.

Summary

In this article, we have explained the following about hollow motors:

- What is a Hollow Motor?

- Two Advantages of installing a Hollow Motor

- Main Applications of Hollow Motors

- Mabuchi Motor's Hollow Frameless Motors

Hollow motors allow power lines, network cables, air tubes, etc. to be placed through the hollow point in the center, allowing space saving and equipment miniaturization. The smaller the equipment, the fewer parts are needed, which can even reduce the number of man-hours required.

Mabuchi Motor's hollow frameless motors IA/IB Series are recommended for cooperative robots and products with built-in structures. Four types of motors with different outputs are available, allowing you to select the motor that best suits the structure and size of your product.

Our representatives will support you in your purchase, so that even first-time buyers can use our products with confidence.

If you are interested in our products, please feel free to contact us.